Mud and the BOP

Mud and the christmas tree, aka a blowout preventer

(BOP) are the main means of control of a deepwater

oil well. People who drill for deepwater oil from

drill ships know the dangers. They know that an

unstoppable geyser of mud, methane and oil can erupt

if a mistake is made.

The patent for the rotary

drill bit bit was assigned to Howard Hughs, Sr.

in 1909. You could say the rotary drill bit launched

the Age of Oil. The drill bit is screwed into the

drill

pipe which extends all the way from the drillship

to the bottom of the well. The drillship rotates the

drill pipe to drive the drill bit. Drill pipe comes

in 33 foot sections that screw together. The drill

pipe is made of strong steel and it is typically 7

inches in diameter with 2 inch thick walls.

Here are two videos explaining oil well drilling.

http://www.youtube.com/watch?v=EUAaMHxCEC0&feature=related

http://www.youtube.com/watch?v=3Xu8COD5pgM

Mud

A highly engineered fluid,

called mud, is forced down the drill pipe and up the

outside of the drill pipe to the drillship. There,

the cuttings are removed and the mud is sent down for

another round trip. The weight of the mud serves

another purpose. It prevents oil from rising to the

surface.

A highly engineered fluid,

called mud, is forced down the drill pipe and up the

outside of the drill pipe to the drillship. There,

the cuttings are removed and the mud is sent down for

another round trip. The weight of the mud serves

another purpose. It prevents oil from rising to the

surface.

It is possible to calculate the specific gravity (SP)

of the mud required to exactly balance the pressure

in the Macondo Prospect reservoir. It was explained

previously how to calculate reservoir pressure which

is 1142 bars. The pressure, in bars, due to the mud

in the drill pipe at the depth (5486 meters) of the

reservoir is;

pressure = SP * 5486 / 10

Set reservoir pressure equal to mud pressure and

solve for the specific gravity;

SP = 1142 / ( 5486 / 10 )

SP = 2.08

Mud with a specific gravity of 2.08 will neither ooze

down into the reservoir nor rise up. A near balanced

state is desired when drilling a deepwater well.

It is common to encounter pockets of liquid methane

while drilling. The methane is carried up with the

mud. The methane becomes a gas and so occupies much

greater space as it nears the surface. This rapidly

displaces mud which shoots up. In industry parlance,

the oil well has "kicked." The displaced mud also

means the well is unbalanced. Small, infrequent kicks

are only a small problem. They can be countered by

using heavier mud and pumping it faster. Big and

frequent kicks are a big problem. A really big kick

is a blowout--there is no sharp line.

Almost all deepwater oil wells kick, but the Macondo

Prospect well kicked more than most. This explains

why BP was behind schedule and impatient to move to

the next drilling site.

It is possible to make really heavy

mud by adding barium sulfate--which is also used

to make the barium enema used to visualize the colon

in x-rays.

The blowout preventer (BOP)

The name

suggests that the BOP does only one thing--prevent

blowouts. But in reality, the BOP does many things.

The BOP is the second as well as the last line of

defense against blowouts. Everything passes through

the BOP including drill bits, drill pipe, well

casings, well liners, oil, gas, mud, cement etc. To

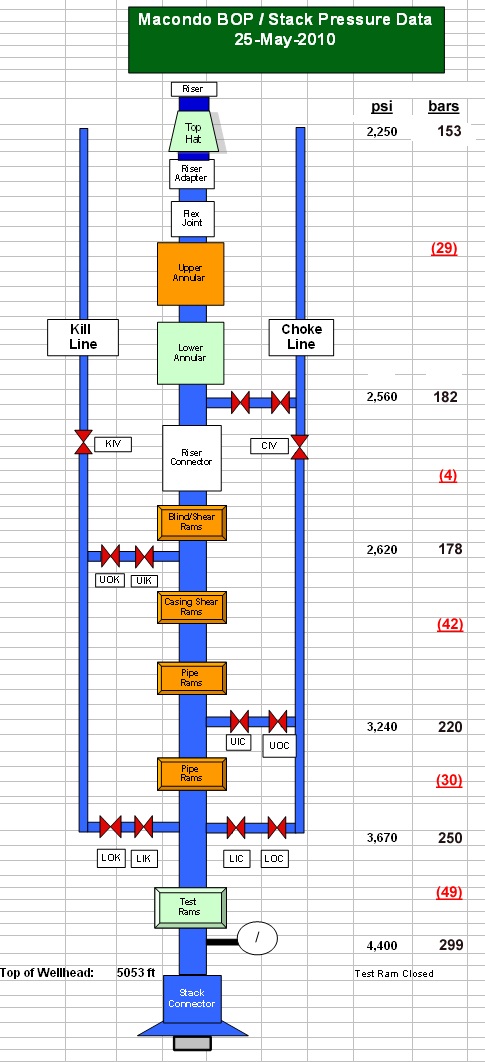

the right is a schematic diagram of the Deepwater

Horizon BOP. Almost everything on the BOP is

duplicated to make it failsafe. I found the schematic

at http://www.theoildrum.com/node/6611#more

The name

suggests that the BOP does only one thing--prevent

blowouts. But in reality, the BOP does many things.

The BOP is the second as well as the last line of

defense against blowouts. Everything passes through

the BOP including drill bits, drill pipe, well

casings, well liners, oil, gas, mud, cement etc. To

the right is a schematic diagram of the Deepwater

Horizon BOP. Almost everything on the BOP is

duplicated to make it failsafe. I found the schematic

at http://www.theoildrum.com/node/6611#more

The original comes from the Department of Energy.

http://www.energy.gov/open/oilspilldata.htm

The schematic actually comes from a spreadsheet. I

have added slightly to it. I will explain later.

http://www.energy.gov/open/documents/4.2_Item_1_BOP_Pressures_07_Jun_1200_Read_Only.xls

The "kill" and "choke lines" carry mud to the lower

part of the BOP. The lines originally ran alongside

the riser to the Deepwater Horizon. While drilling,

mud goes down the bore of the drill pipe.

One of the things the BOP can do is seal the gap

between the drill pipe and the well casing. There are

two of these and they are labeled "annular." They

might be activated if a kick occurs. They prevent mud

from coming up around the drill pipe.

If a hurricane is coming and you are in a hurry, you

might use the casing shear ram to disconnect the

drill ship from the well head. You have to remove the

drill pipe first.

If a blowout has occurred and all counter measures

have failed, you can activate the "blind shear ram".

It is the last chance to avert a catastrophe. It has

a blunt purpose. It shears the pipe casing and drill

pipe. This takes considerable force as the drill pipe

has thick walls and is made of strong steel.

The blind shear ram also completely and permanently

blocks the BOP. It can be activated from several

places on the drillship. It is also automatically

activated when the BOP looses hydraulic or electrical

connection with the drillship. The Deepwater Horizon

disaster occurred as a direct result of the blind

shear ram failing to do its job. The blind shear ram

is the only major BOP component not duplicated.