Background

The Deepwater Horizon blowout story is not over and the whole

story will take years to unfold. But for sure, an

unstoppable geyser of mud, methane and oil did erupt

20 April. The blind shear ram did fail. The hurricane

of methane did find a spark in the electrical

equipment. The resulting explosions did kill 11 and

the Deepwater Horizon did sink.

There seems to be no precipitating event. There was no storm, no tsunami and no collision.

The Macondo Prospect was not especially difficult to drill.

Hundreds of wells have been drilled at this depth successfully.

The Deepwater Horizon was designed to drill much deeper and it had

done so, repeatedly.

The only technical problem was the numerous methane pockets which caused "kicks."

Here is a

good account of what happened that day.

It seem to me a series of short cuts and calculated risks that

went awry caused the blowout rather then a blatant mistake.

Personally, I don't see why there are not more blowouts.

To prevent one, you have to do many things sequentially and correctly.

The

Exxon Valdez spill is small in comparison. The

Ixtoc

blowout of 1979 was the largest ever but the

Deepwater Horizon blowout is on track to exceed it. The Deepwater Horizon

blowout occurs in deep water. That means methane

dissolves in sea water before it reaches the surface.

The oil, because of the high pressure, is broken into

small droplets which rise very slowly. (Think of shaking a bottle of

salad dressing.) The ocean is

contaminated from top to bottom. Nothing like this

has ever happened.

How could such a thing happen?

The pressure

of a deeply buried oil reservoir is like a dragon

sleeping under the impermeable rock seal. When the

seal is broken by the drillbit, the dragon is held in

check by the weight of miles of heavy mud. But to

produce the well, the mud must be replaced by much

lighter water. The water is then pushed aside by the

pressure of the oil and gas. If the pipes and valves

work correctly, the oil and gas goes where intended.

But, as can be seen, the dragon can sometimes

escape.

The pressure

of a deeply buried oil reservoir is like a dragon

sleeping under the impermeable rock seal. When the

seal is broken by the drillbit, the dragon is held in

check by the weight of miles of heavy mud. But to

produce the well, the mud must be replaced by much

lighter water. The water is then pushed aside by the

pressure of the oil and gas. If the pipes and valves

work correctly, the oil and gas goes where intended.

But, as can be seen, the dragon can sometimes

escape.

Why is it so hard to stop an oil leak?

Understanding what the BOP can and can not do is the

key to answering this question. Let's do some more

calculations. If the blind shear ram worked, and the

oil flow was stopped, what would be the pressure just

below the BOP? We previously calculated the pressure

within the reservoir. It is 1143 bars. But there is a

3962 meter column of oil between the BOP and the

reservoir. The pressure due to the oil column is;

0.85 * ( 3962 / 10 ) = 337 bars

The pressure at the bottom of BOP is;

1143 - 337 = 806 bars

The top of the BOP is in deep water which has a

pressure of 152 bars. The blind shear ram within the

BOP would have to withstand the difference between

806 bars and 152 bars which is 654 bars. This is a

lot but the BOP was designed to do this.

But the BOP

has failed and the oil is flowing fast. In order to

make the oil flow, there must be pressure drops. It

is possible to figure out where the resistance to

flow is by measuring the pressure drops.

But the BOP

has failed and the oil is flowing fast. In order to

make the oil flow, there must be pressure drops. It

is possible to figure out where the resistance to

flow is by measuring the pressure drops.

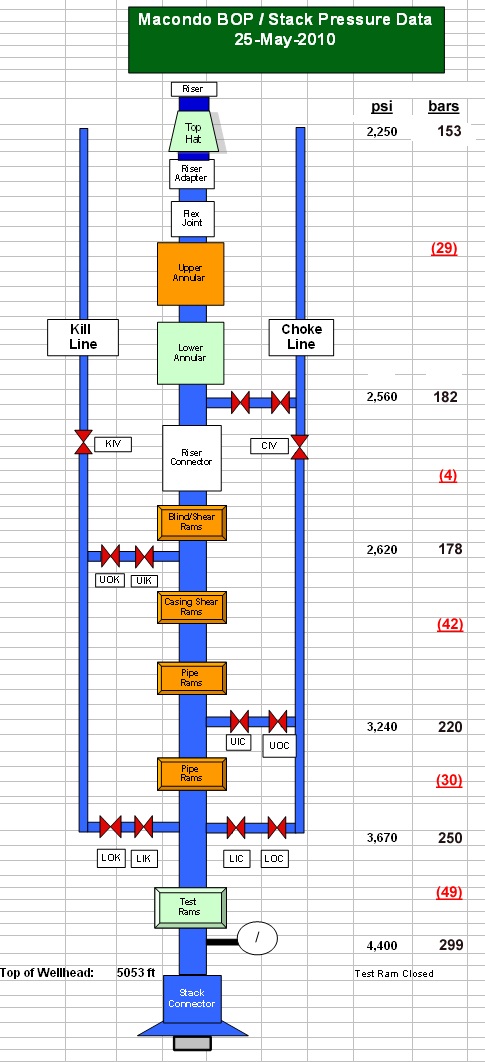

(This BOP schematic also appears on the previous

page. The right hand column has been added.) Pressure

readings from within the BOP appear along the right

hand side. The red numbers correspond to pressure

differences. The red number "(4)" next to the blind

shear ram proves it does not restrict flow much. A

reading of 4 means the blind shear ram completely

failed.

The "annulars" drop 29 bars, the casing shear rams

and the pipe rams drop 42, another pipe ram drops 30,

and, oddly, the test rams drop 49. Altogether, the

pressure drop is 146 bars. The BOP is resisting the

flow of oil and gas to some extent.

We are now in a position to understand the "top kill"

attempt. The basic idea was to pump mud through both

the "kill" and "choke" lines fast enough to drive mud

down to the reservoir. The top kill was combined with

a "junk shot." The idea was to use the kill and choke

lines to introduce cunningly shaped pieces of rubber

which would get caught in the upper parts of the BOP.

BP ransacked the Gulf to get sufficient mud. BP had a

30,000 horsepower mud pump so they had that covered.

The mud pumping rate was limited by the pressure the

BOP could withstand. When that limit was reached, it

was determined that the mud was going up, not down.

Fearing damage to the BOP, BP shut down the mud

pumps. Top kill failed because the BOP did little to

slow mud flow out the top.

Destroying the BOP would have been disastrous for two

reasons. Oil flow would increase and there would no

chance of controlling the blowout.

A very nice description of the top kill attempt

appears in the

New York Times.

What would happen if the BOP failed?

If the blind shear ram had worked, the pressure at

the base of the BOP would be 806 bars. The actual

pressure is 299 bars. The difference, 507 bars, is

due to resistance to flow.

What would happen if the BOP failed completely and no

longer resisted flow? The engineering

formulas needed to calculate flows are complex,

but it is possible to extract an approximation. The

approximation is this; The flow rate is proportional

to the square root of the pressure drop. Plugging in

the numbers;

flow rate = square root of ( 806 / 507 )

flow rate = 1.26

Oil flow rate would increase 26 percent and there

would be little hope of stopping it.